Description

1. Condenser Coil

Application:

Slab coil and Coil with a various bending radius

Residential and commercial HVACR

Condition:

- Refrigerant R410A, R134A, R22, R407C, R404A

- Design pressure 650psi(4.5MPa)

- Ambient air temperature -30°C to 72° C (-22 °F to 1 61.6°F)

- Expected refrigerant temperature -30°C to 121°C (-22 °F to 250°F)

- Storage temperature -30°C to 121°C (-22°F to 250°F)

Feature:

- Up to 50% less refrigerant charge

- More than 30%higher HT efficiency

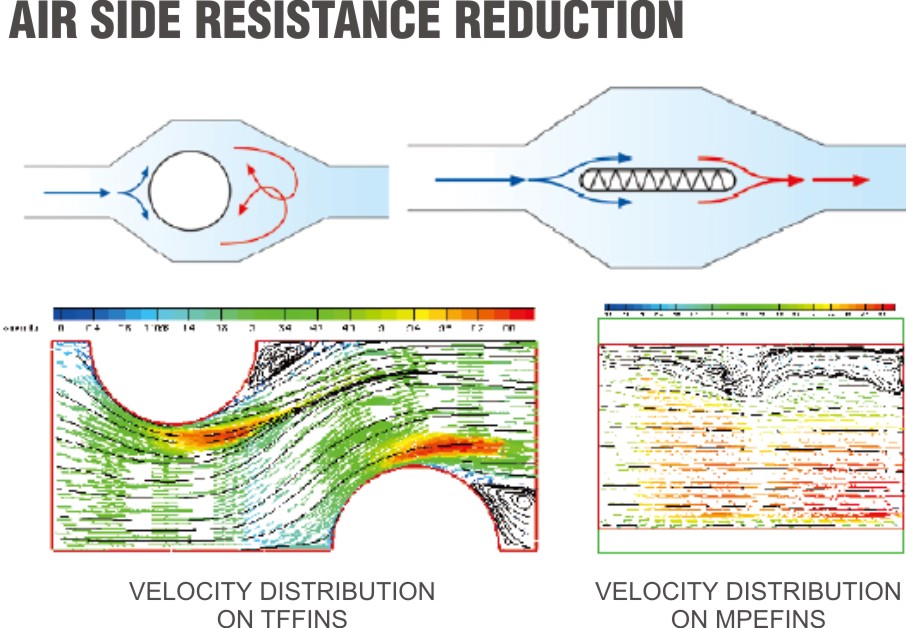

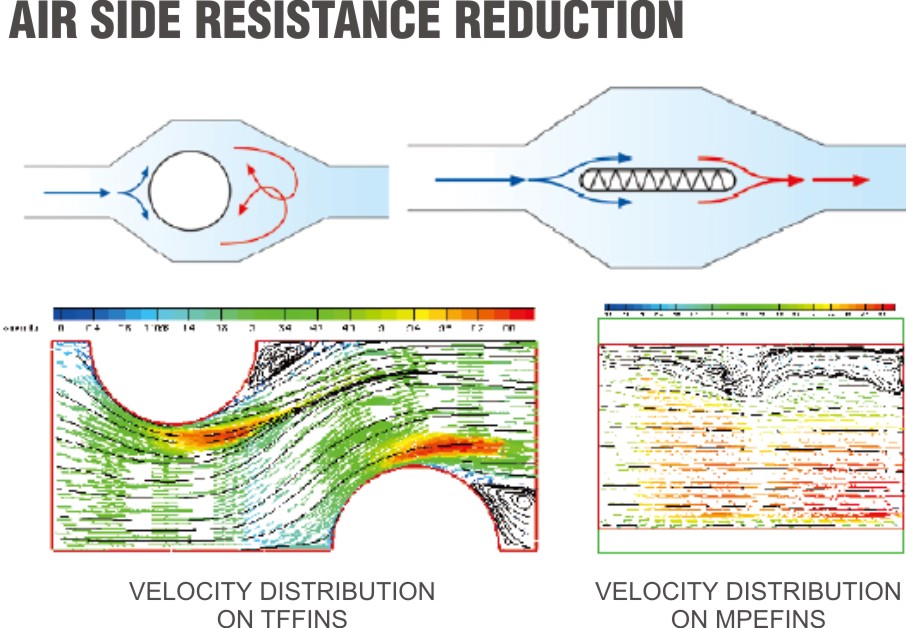

- Up to 30% lower air side DP

- Lighter in weight, less volume: up to 50%

- 100% Aluminum, easy to recycle

- Minimum performance decrease with lifetime (100%brazed)

- Minimum galvanic corrosion (100%Aluminum)

2. Evaporator Coil

Application:

- Slab coil

- Residential and commercial HVACR

- Mass production for A-Coil

- Indoor air conditioner and heat pump capability

- A-Coil (Tube bending)

Condition:

- Refrigerant R410A, R134A, R22, R407C, R404A

- Design pressure 650psi(4.5MPa)

- Ambient air temperature -30°C to 72°G (-22 °F to 161.6 °F)

- Expected refrigerant temperature -30°C to 121°C(-22 °F to250 °F)

- Storage temperature -30°C to 121°C (-22 °F to 250 °F)

Feature:

- Up to 50%less refrigerant charge

- More than 30% higher HT efficiency

- Up to 30%lower air side DP

- Lighter in weight, less volume: up to 50%

- 100%Aluminum, easy to recycle

- Minimum performances decrease with lifetime (100% brazed)

- Minimum galvanic corrosion (100% Aluminum)

- Special tube bending structure for A-coil

- Special design for good refrigerant distribution

- Special fin design for good water drainage

Specification

Core Size

Core depth:16mm(0.63″),20mm(0.787″),25mm(1″),36mm(1.434″),+customized depth

Available max sizes:2.5mx1.6m(98.4″x63″)

optional finishing or coating

Powder coating:Dacromet, Black enamel coating,E coat

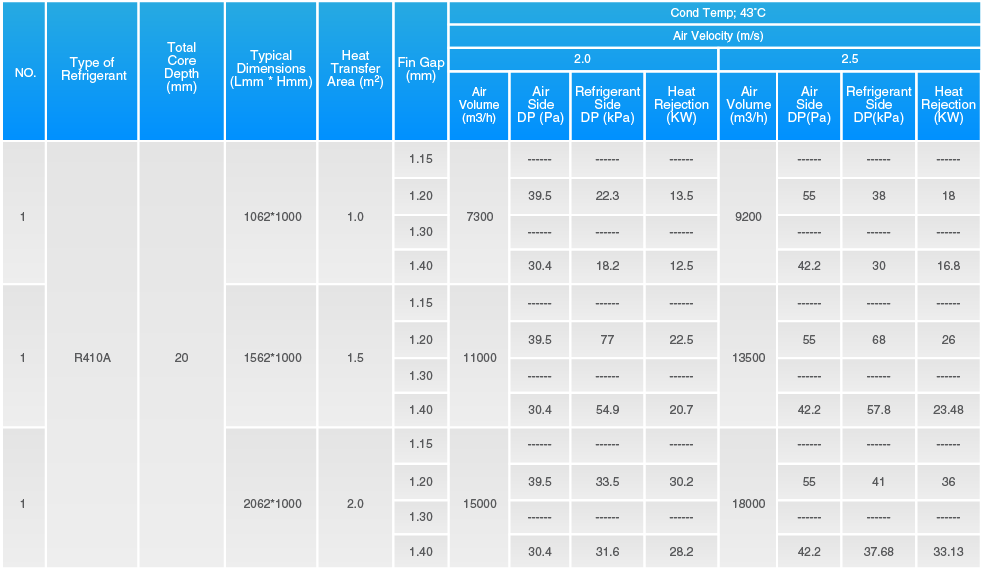

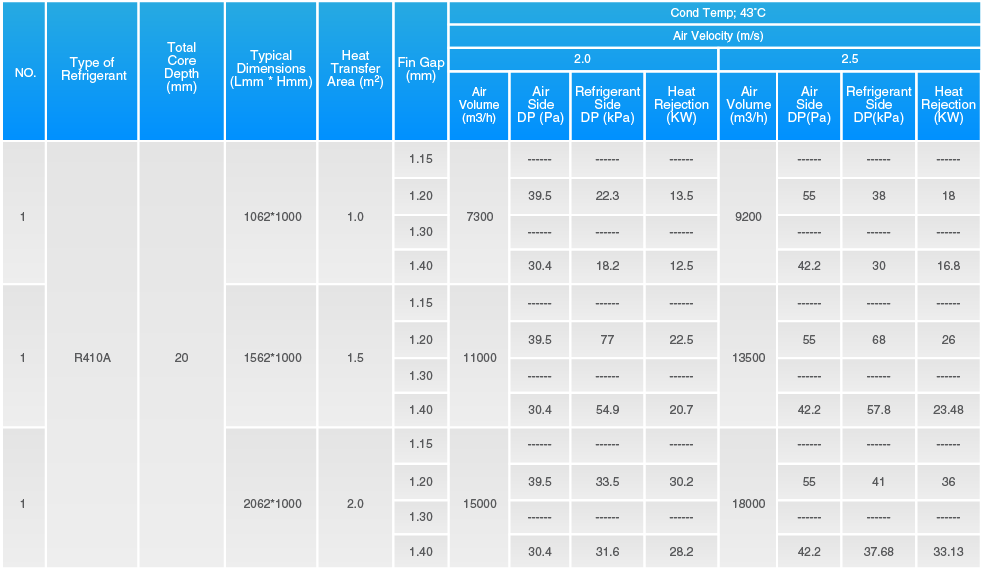

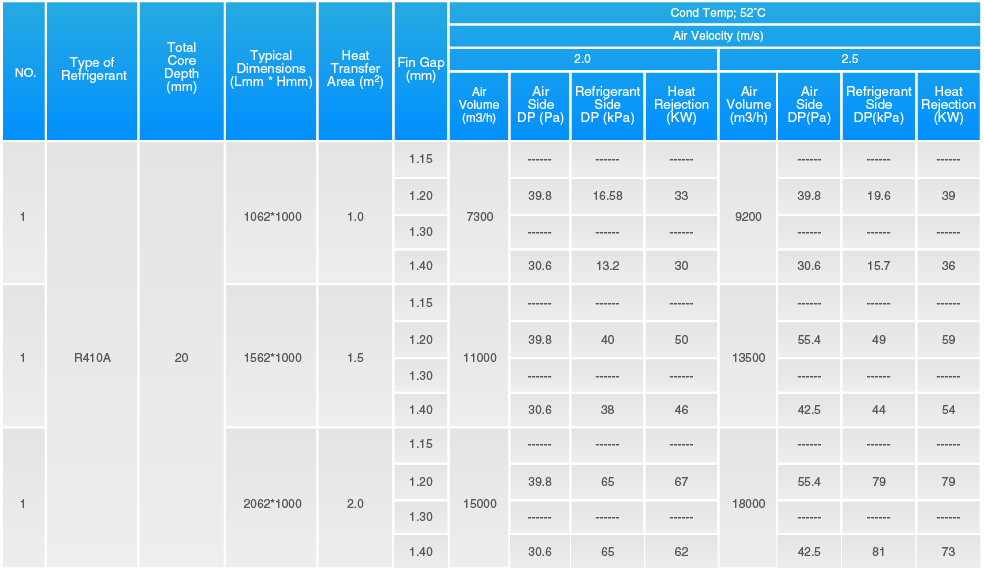

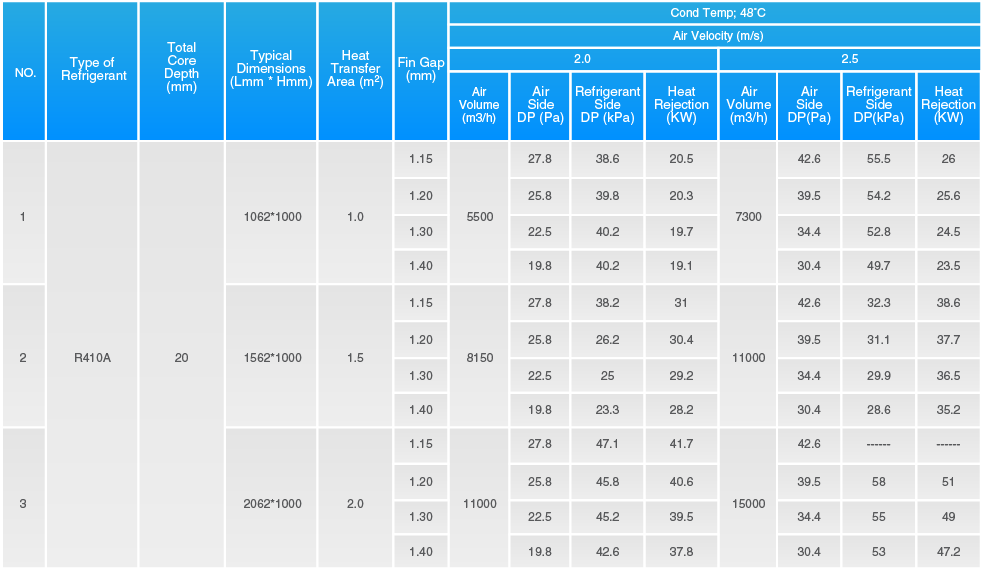

Model selection guide*

Model selection guide*

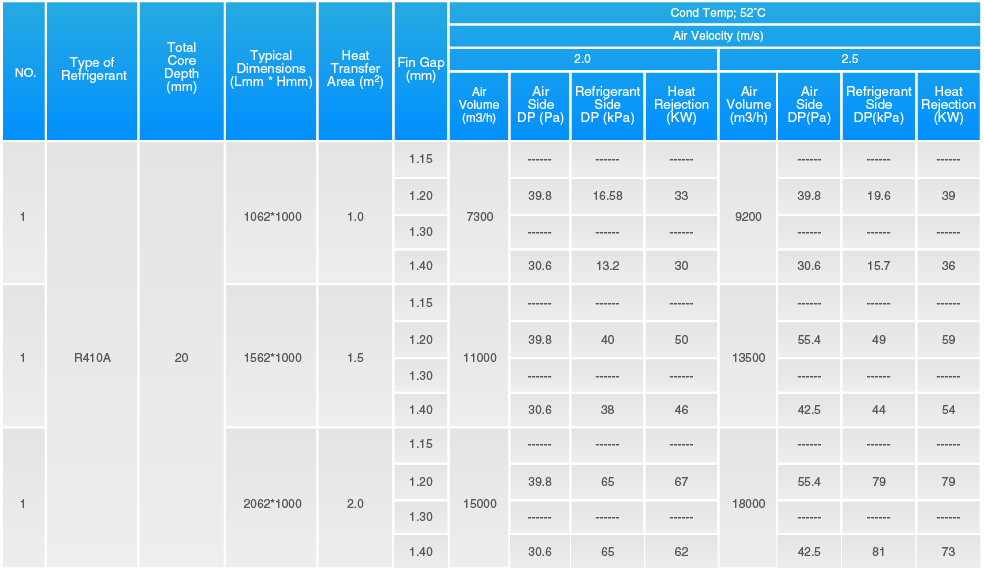

Model selection guide*

Model selection guide*

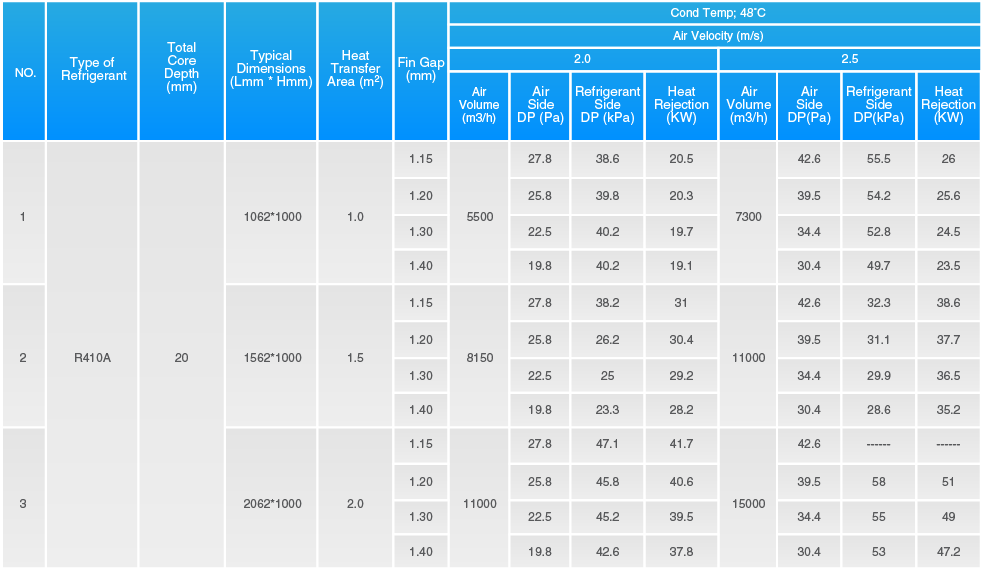

Model selection guide*

Model selection guide*

*The subject selection is for reference only, the final selection is to be decided by customer’s specification.

Reviews

There are no reviews yet.